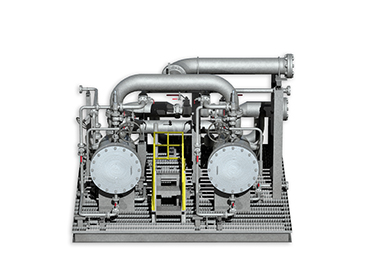

P-KLONE™ Hydrocyclone Oil-Water Separation

The P-KLONE™ Hydrocyclone is a highly efficient and economic approach to processing oil-laden water. It is a well-proven method for taking water from the production separator with oil concentrations up to 5% and readying it for secondary treatments such as induced gas flotation or filtration. The hydrocyclone can be designed to handle any flow volumes and output pressures you require. P-Klone is small, lightweight and insensitive to orientation or motion, making it an ideal solution for offshore and space-constrained onshore applications.

Key Benefits

Cost-Savings

- A cost-effective, efficient way to reduce oil concentration prior to secondary de-oiling.

- Eliminates the cost of a feed pump by using existing process pressure.

- Easy to ship, install and startup, making it ideal for temporary and long-term projects.

Better Performance

- Low risk technology, with nearly 30 years of proven performance and thousands of units in service.

- Easy to maintain with no moving parts, no failure-prone mechanisms, and no fugitive emissions.

High Flexibility

- Works flawlessly regardless of orientation or pitch and roll motions offshore.

- Wide turndown range allows flow rates ideal to your operation.

How It Works

Standard Features & Options

Standard Features

- ASME code pressure vessel, vertical or horizontal orientation

- Flanged liner access

- Complete process review

Material of Construction

- Pressure vessel: internally coated carbon steel

- Support plates: coated carbon steel

- Internals: Duplex 2205

Standard Options

- Blanking liners to adapt for low-flow conditions

- Pump-driven system

- Skid, piping, instrumentation and controls

- Water characterization services

- Chemical selection and supply

- Upgraded materials for vessels, internals, valves, instruments, piping (Duplex SS, Hasteloy)

- Ancillary equipment such as transfer pumps and chemical injection

- Cold-weather protection such as skid enclosure and insulation

- Other options as required to meet your specifications