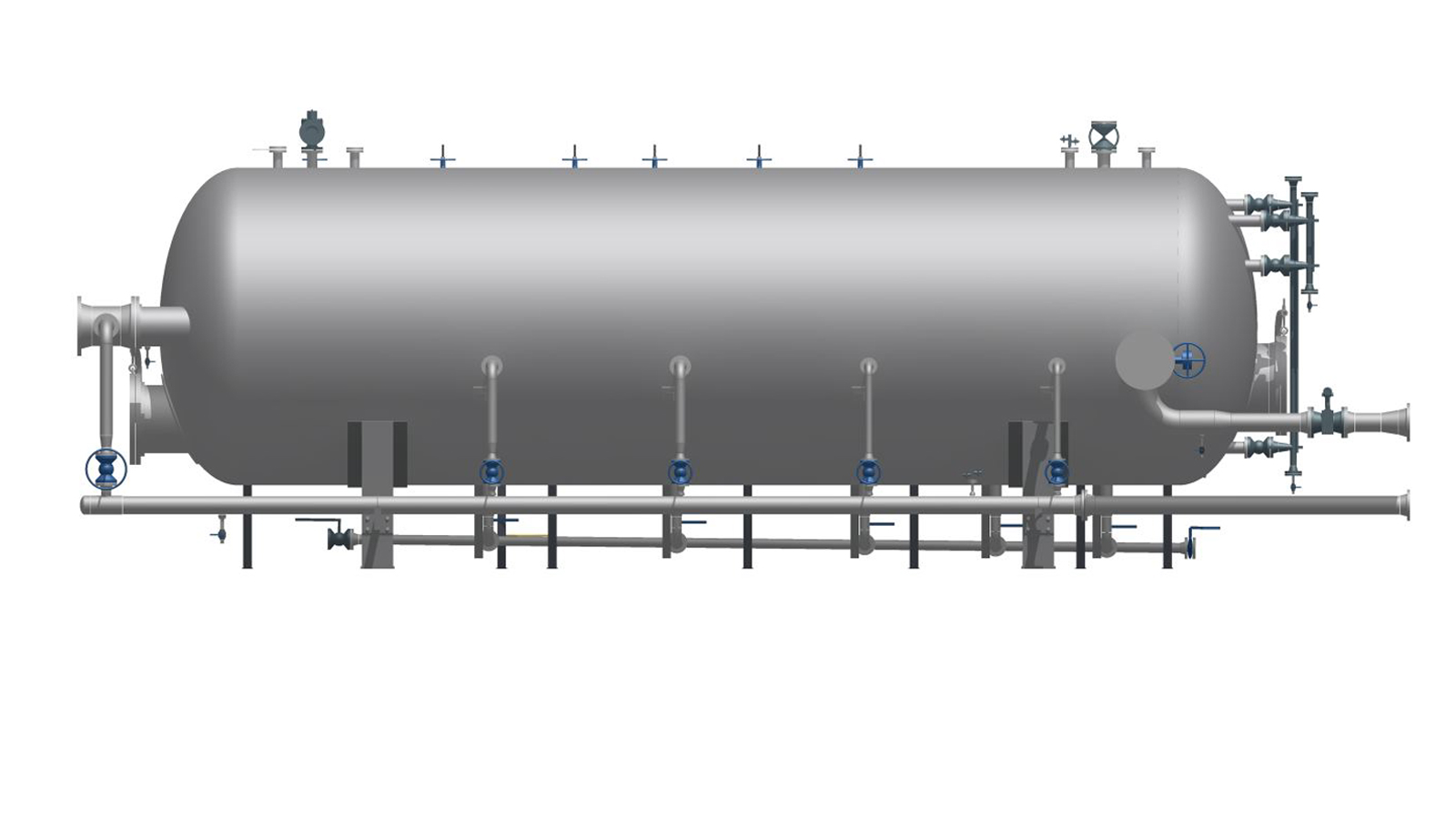

Revolift® HS

RevoLift® HS takes oil separation performance far beyond typical induced gas flotation systems. As produced water moves continuously through multiple chambers, microbubbles are introduced to lift the smallest suspended oil particles to the surface where they are skimmed off, resulting in clean outputs. The system is purely hydraulic with no internal moving parts, providing continuous, trouble-free separation at rates up to 150,000 BWPD in a single vessel. Its multi-chambered, sequential treatment design handles variable flows and upsets without performance impact or short-circuiting.. The Revolift HS can be custom designed to meet all of your specifications and solve your water problems.

Key Benefits

Cost-Savings

- Efficient pre-engineered design reduces capital costs

- No moving parts, which reduces costly failures and delays

Better Performance

- Sequential treatment ensures thorough oil removal

- MBF technology ensures cleaner water in the most challenging processes

- High tolerance for upsets due to multi-chamber design with no short-circuit paths

- No rotating seals, thus eliminating fugitive air emissions

High Flexibility

- High-quality, wide operating range makes this treatment system a long-term asset

- Wide turndown range handles variable flows without performance loss.

How It Works

Standard Features & Options

Standard Features

- ASME code pressure vessel

- Hydraulic skimming

- Microbubble technology via ONYX® pump

- Fully automated controls

- Complete process review

Material of Construction

- Vessel: internally coated (NACE MR 0175) carbon steel

- Piping: internally coated (NACE MR 0175) carbon steel

- ONYX pump: Duplex SS

Standard Options

- Skimmings collection tank

- Skimmings transfer pump

- Water characterization services

- Chemical selection and supply

- Upgraded materials for pumps, valves, instruments, and piping

- Ancillary equipment such as transfer pumps and chemical injection

- Insulation