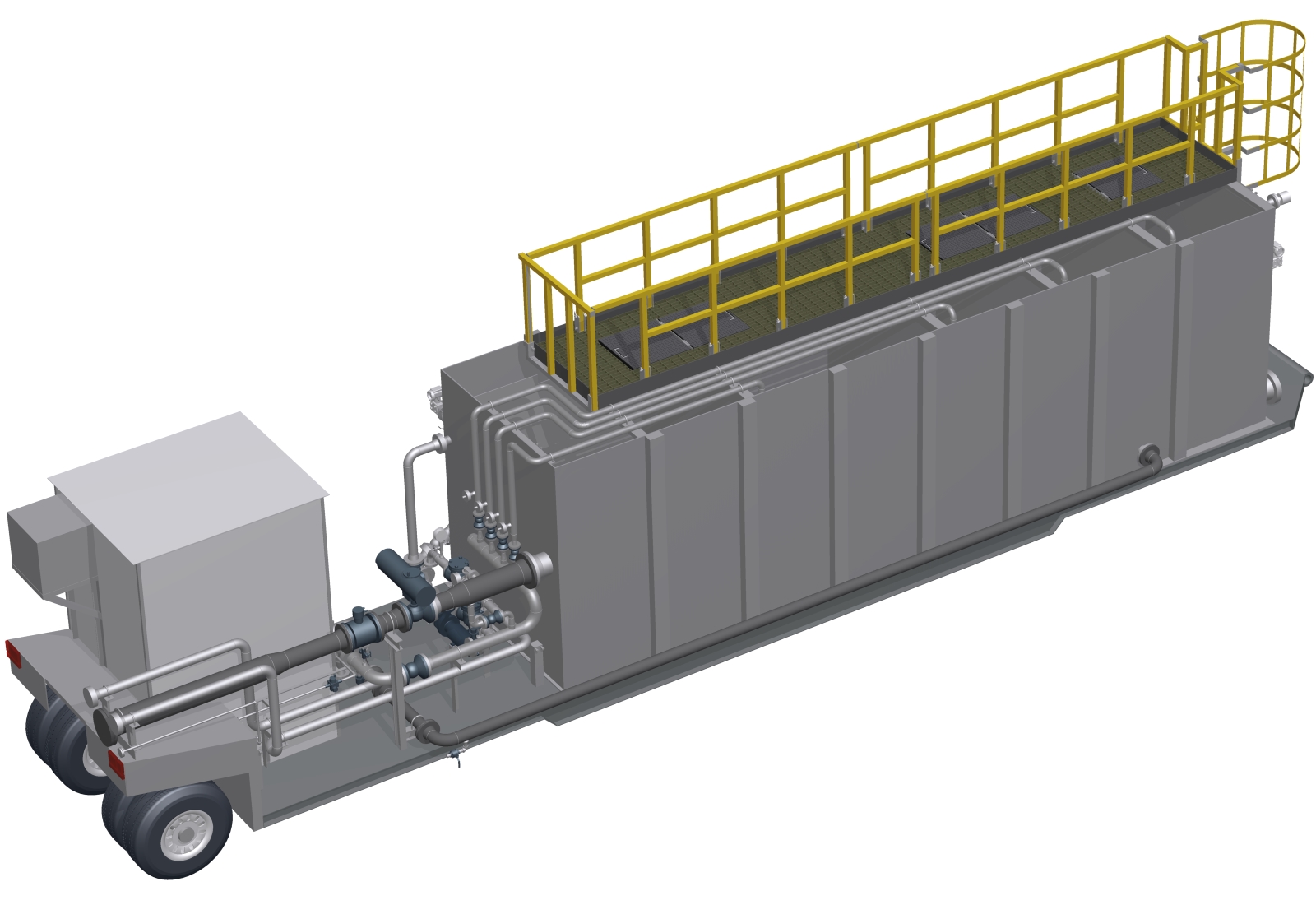

Revolift® SP

Designed to cater to the Shale Play market, the RevoLift® SP is a reduced cost version of its sister product, the RevoLift® VS. Utilizing Exterran®’s patented microbubble flotation technology (MBF®), the RevoLift SP floats out contaminants separately from oil allowing for efficient oil recovery. The entire solution is trailer mounted allowing for quick shipping, installation, and commissioning with minimal engineering and site preparation. A single mobile unit can handle flow rates from 0 to 30,000 BWPD. This system operates hydraulically with no internal moving parts resulting in a wide turndown range, high tolerance for upsets, and nonstop performance.

Contracting Models

- Lease

- Purchase

- Contract Operations

- Purchase + O&M

Key Benefits

Cost-Savings

- Pre-engineered design

- Fleet inventory allows for quick turnaround and simple deployment logistics leading to lower capital costs.

- Substantially lower tie-in costs compared to high-spec systems.

- Lower chemical consumption resulting in reduced chemical costs.

- Open tank design eliminating the need for a blanketing system.

- No moving parts within the tank, reducing costly failures and delays.

Better Performance

- Exterran® separates oil, then floats the suspended and precipitated solids, while others wait for solids to settle.

- 5 chamber flotation tank eliminates short circuiting and handles slugs.

- High tolerance for process changes due to multi-chamber design with no short-circuit paths.

High Flexibility

- Compact, self-contained design is easy to ship, install, and commission.

- Ability to treat difficult fluids such as frac flow back applications.

- Modular designed to quickly connect to our desanding and filtration products if the process requires.

- Remote monitoring and operation.

- Autonomous operations and shutdowns through built-in PLC offering various control philosophies.

- Quick delivery to move operations forward and achieve goals sooner.

How It Works

Standard Features & Options

Standard Features

- Hydraulic skimming

- Microbubble technology via ONYX® pump

- Dedicated clean oil collection chamber and transfer pump for oil recovery

- Separate sludge collection and transfer pump

- Instrumentation and PLC for full automation with various control options including remote monitoring and data acquisition

Material of Construction

- Tank: internally coated carbon steel

- Piping: FRP

- Instruments: 316 SS wetted parts

- ONYX pump: Duplex SS

Standard Options

- Water characterization services

- Chemical selection and supply

- Ancillary equipment such as transfer pumps and chemical injection